Stretch hood film manufacturer is an important process in the packaging industry. It involves the production of stretchable plastic film, which is used to secure and protect items during shipping and storage. The stretch film industry has grown significantly over the past few decades due to its superior strength, flexibility, and cost-effectiveness. This article will provide a comprehensive overview of the process for stretch film manufacturing, including raw materials used, process steps involved, equipment required, and advantages of using this type of packaging material.

Types of Stretch Film Manufacturing

Stretch film is an essential packaging material used for wrapping and securing products for shipping and storage. It is a strong and versatile material that is widely used in many industries, from food processing to automotive manufacturing. Stretch film manufacturing involves a variety of processes depending on the type of product being produced. The three most common types of stretch films, including those used for round bale wrap, are cast stretch films, blown stretch films, and pre-stretched films. Cast films are made by extruding molten plastic resin through a die-casting machine which forms thin layers of plastic that are then stretched over a mandrel or roller to form the desired shape.

Raw Materials Used in the Production Process

Raw materials are the foundation of any manufacturing process, and their selection can have a significant impact on the quality of the end product. The amount and type of raw materials used will depend on the desired outcome, as well as budget constraints. For this reason, it is important for businesses to carefully consider which materials they use to optimize their production process and create a high-quality product.

Raw material selection typically begins with an assessment of what type of material is needed for a particular application. This could include wood, metal, plastic or other kinds of materials depending on the needs at hand. Once the right material is identified, further decisions must be made regarding its grade (the quality), quantity and cost. Companies may also choose to source their raw materials from different suppliers to obtain better prices or higher-grade products if necessary.

Manufacturing Process for Stretch Film

Stretch film is a versatile and widely used product in many industries. It is used to wrap products together, secure them for transport, and protect them from dirt and moisture. The manufacturing process for stretch film involves several steps that ensure the highest quality product possible.

The first step in the manufacturing process is the selection of raw materials. This includes high-quality polymers such as polyethene or polypropylene that are capable of being stretched without breaking or tearing. These materials must be carefully chosen based on their specific properties, such as flexibility, transparency, tear strength, puncture resistance, etc., to ensure they meet the desired performance requirements.

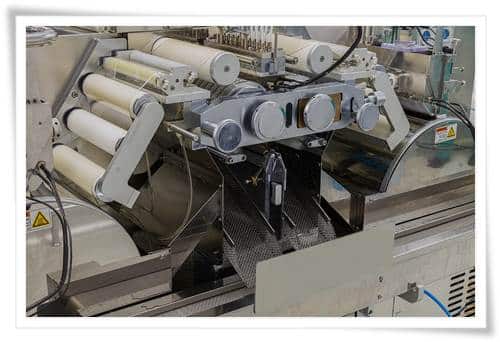

Once the raw materials have been selected they are melted down into pellets which are then fed into an extruder machine where they are heated and forced through small openings known as dies which form them into thin sheets of plastic material known as “film” or “foil” depending on their thicknesses.

Packaging and Delivery Requirements for Stretch Film

Packaging and delivery requirements for the stretch film are essential considerations when shipping products. Stretch film is a plastic material used to protect, secure, and stabilize items during transport. It is highly elastic and offers high-clarity protection that can be customized to a variety of shapes, sizes, and weights. However, if not properly packaged or delivered, the stretch film may not provide optimal protection for the items inside. When it comes to packaging stretch film for delivery purposes, several important factors must be taken into consideration. First of all, the size of the stretch film must be appropriate for whatever is being shipped.

Quality Control Measures Adopted in the Production of Stretch Film

When it comes to the production of stretch film, quality control measures are essential. Stretch film is a versatile material used to bind and secure loads for transportation, storage and protection from theft or tampering. Because of its importance in the distribution chain, stretch films must be manufactured with strict quality standards in place.

The first step in ensuring quality control for stretch films is the selection of raw materials. Careful consideration must be given to the type of plastic resin used as well as any additives that may be required during production such as lubricants or UV stabilizers. Quality control teams will evaluate each potential supplier and perform thorough testing before selecting a vendor that can meet their standards for consistency and reliability.

Once raw materials have been selected, they are carefully monitored throughout the entire manufacturing process.

Conclusion

In conclusion, stretch film manufacturing is a highly specialized process that requires the use of advanced technology to produce high-quality products. The process involves the application of heat and pressure to create a thin, flexible film with exceptional strength and elasticity that is well suited for wrapping and protecting items during transportation or storage. The result is a product that offers superior protection against moisture, dust, dirt, abrasion, puncture and other forms of damage. Stretch films are an essential part of the supply chain for many industries worldwide.

Leave a Reply

You must be logged in to post a comment.